Alder Color Can Calibrate Your Press Remotely WITHOUT a DEDICATED PRESS RUN!

By Bill Owen – Alder Color – Senior Color Technician

Examining the Alder Color Control Platform.

What if I told you that I could calibrate your press without being on-site with your press operator? It’s a hard concept to grasp, right? But it’s actually fairly simple with our Alder Color Control Platform. Let me explain.

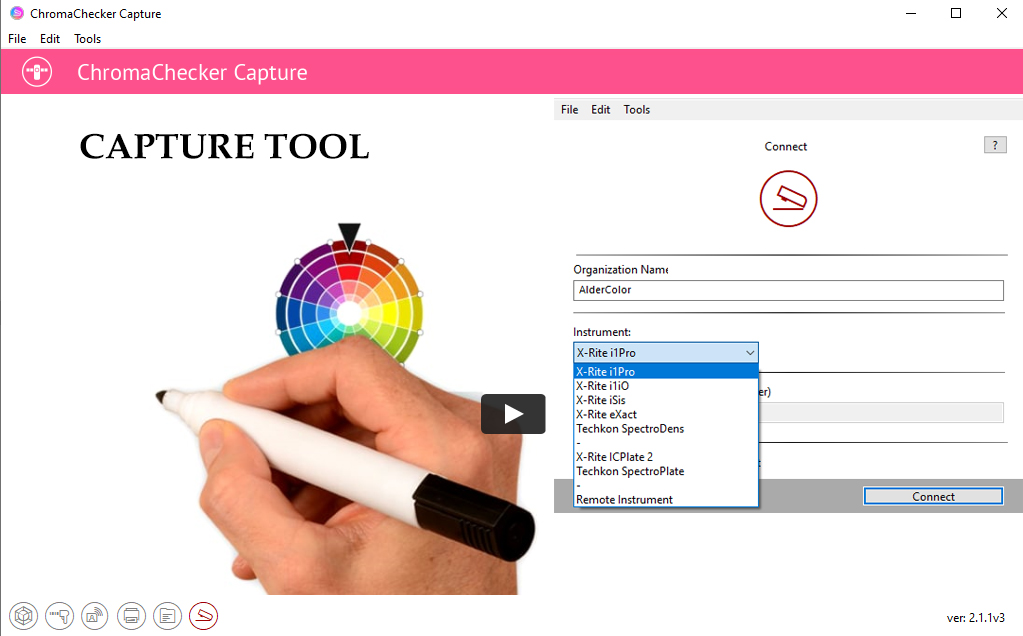

All that’s required on your end is that you have a measurement device and a human available to measure a 1 row or 3 row control strip. If you don’t have a measurement device, we can rent one to you for the day. Our technicians typically use the X-Rite i1 Pro 3, but you could also use an older i1 Pro or Pro 2, or an X-Rite eXact or even a Techkon SpectroDens. Most every print shop these days has at least one i1 Pro of some sort on hand, or one of the other devices mentioned, so we can likely use what you have. For best results we use the newer i1 Pro 3, but even with an older i1 Pro we can get great curves.

HOW CAN WE DO THIS REMOTELY?

We can take a couple of different approaches. We can send you a press form that contains all of the required control strip options and you could actually do a dedicated press run with that press form. OR… we could provide you with the 1 row and/or 3 row control strips and you can place them on your live work, in a gutter, or wherever you might have space. Run your live work as usual and save some sheets to measure. We recommend that after you get up to density on an offset press, you run at least 1000 sheets thru the press and pull 1 sheet for every 100 sheets printed for a total of 10 sheets final sheets to be measured. We do this to capture the fluctuation of the press as it’s running. This is also a good approach for a digital press, although they don’t fluctuate quite as much as offset.

WITH AN INKJET PRESS/PRINTER (grand format, wide format, etc.) it’s not necessary to run 1000 sheets. Just run one sheet/press form or a few control strips by themselves and we can measure those. It’s good to measure at least a few to get an “average” which makes for a better curve than if you were to measure just one control strip.

BUT WAIT! HOW DO WE COLLECT THIS MEASUREMENT DATA?

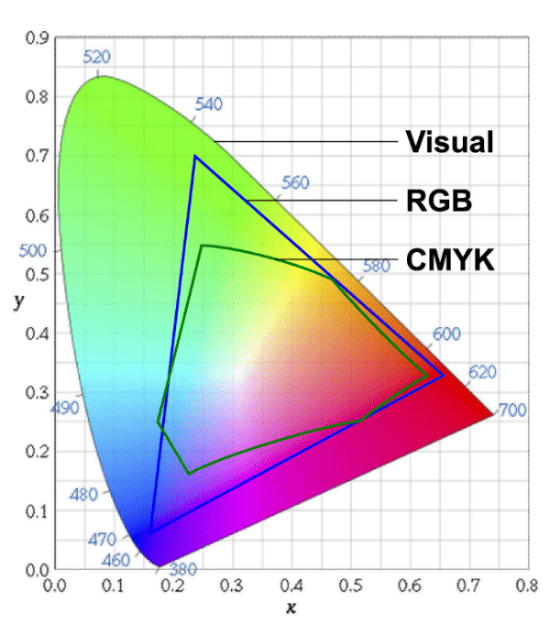

Good question! We use a software application called “CAPTURE” that runs on either Mac or PC and supports connectivity to many popular measuring devices.. We can install and configure this software for you remotely so that all you have to do is measure the control strips. We will guide you through the process of measuring the control strips which typically only takes 5 to 10 minutes. The measurement data gathered is instantly uploaded to the cloud in a “TRACK”. Once all of the control strips are measured, we are able to examine the data uploaded to the TRACK for conformance of each primary color (CMYK) or overprint colors (RGB) as well as neutral gray balance compared to an industry standard or specification, like GRACoL or SWOP. We then group all measurement files and “CALCULATE” a correction curve that will force the press into compliance. Then we can export that curve data from the cloud, in several different formats that are able to be imported directly into your Color Management RIP or Platesetter RIP remotely. If you have a RIP that is not yet supported for file export, we can simply just type in the numbers manually. We will use TeamViewer to log into each computer that you’re using to help guide you through the process and to export and import data into the correct locations.

ARE WE CREATING NEW CURVES or ADJUSTING EXISTING CURVES?

Another good question. We can do both. If you feel that your existing curves are “close” but just need a little tweaking, we can input your existing curve data into the “TRACK” and then tell the software to use that existing curve data as our baseline to calculate the new measurement data with. This will “adjust” your existing curve rather than creating a new curve based on a LINEAR baseline.

DO YOU WANT TO KNOW HOW YOU’RE PRINTING?

The beauty of all of this is that if you like how it works, you can choose to purchase a “TRACK” or a bundle of tracks from Alder Color for each device that you want to monitor and/or calibrate. This will not only provide great quality control tools, but also give you the ability to adjust curves at your leisure. It’s just a fantastic way to monitor your print quality and maintain stability within the print process. Adjust curves as you need to, whenever you need to. As you’ll find, it only takes a few minutes.

SAVE BIG $$$ BY CALIBRATING REMOTELY!

Yes! Always a bonus, right? If we don’t have to travel to you, you don’t have to pay for travel expenses to have a tech on-site. We are also able to discount our daily/hour rates as we can work from our office rather than travel to you. THE FUTURE IS REMOTE CALIBRATION!

HEALTH and SAFETY

With the ever-fluctuating covid mandates, you may not feel comfortable having an outsider come into your facility. This is a great way to get your equipment calibrated safely, quickly and efficiently.

HOW DO WE GET STARTED?

Reach out to Bill Owen at [email protected] and he can schedule a FREE CONSULTATION and create a customized quote for you based on how many devices you want to calibrate, measurement device, needs, TRACK or BUNDLE pricing, etc.

We look forward to launching you into the future of remote color management.