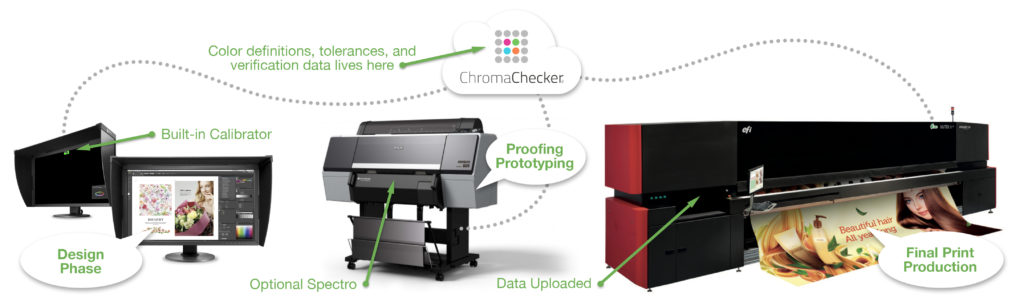

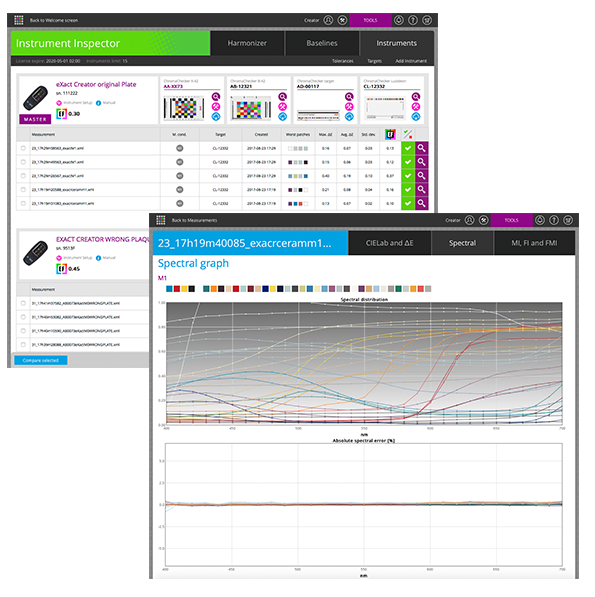

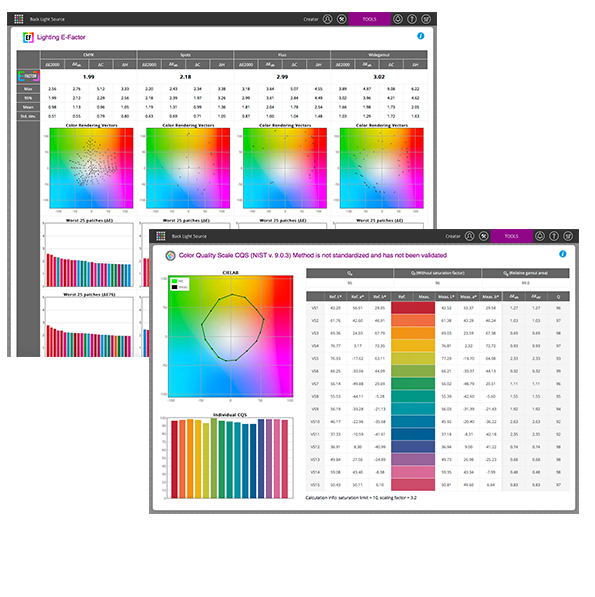

Provides information and reports to ensure plants/manufacturers are in color compliance.

Real-tie information accessible via web browser, iPad or iPhone app, or scheduled via email.

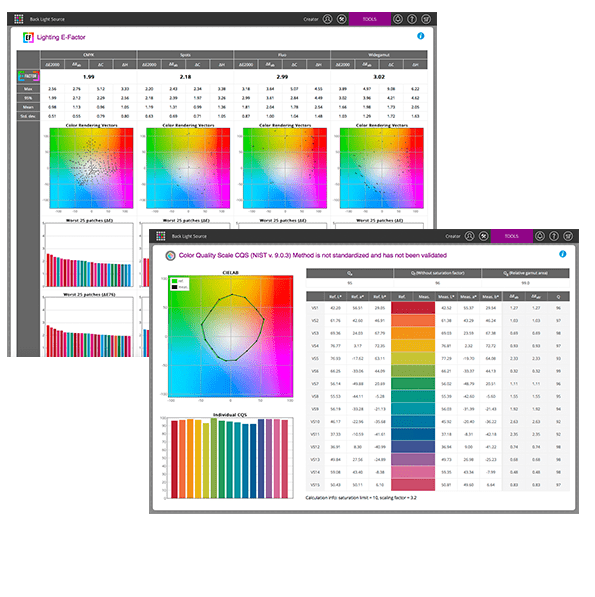

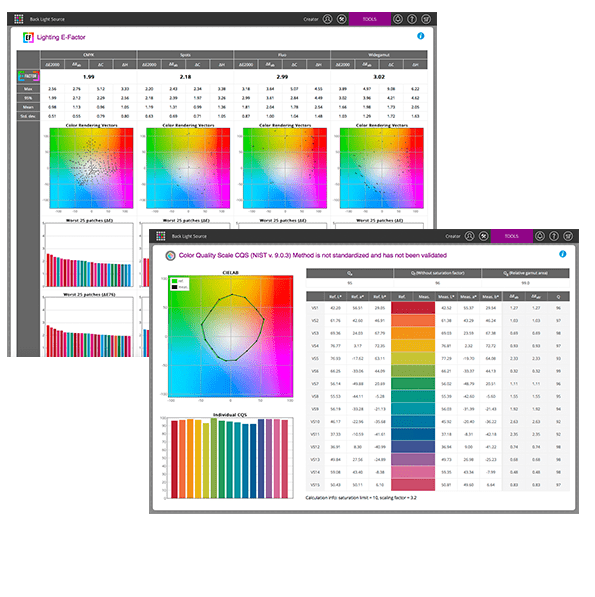

All international standards and regional specifications are provided for comparison.

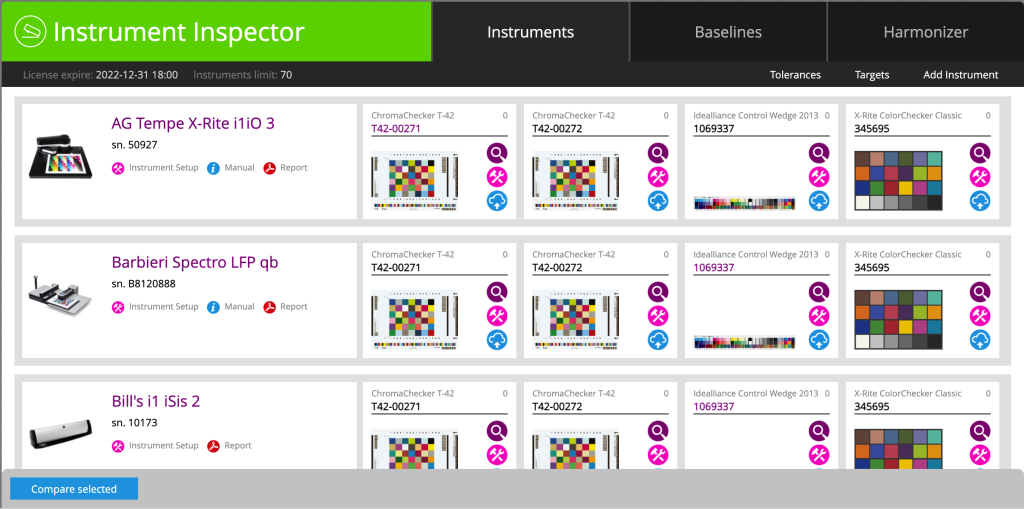

Custom references/targets and tolerance sets can be easily created to compare devices to OK sheet or baseline.

Works with any existing process conrol hardware/software, as long as measurement data can be exported.

Includes uploader software for Mac and PC that can watch any folder and automatically upload data to the proper track.

For printing devices where existing color measurement is not in place yet, there’s another software application called Capture that connects directly to most spectrophometers on the market.

Compliments ink formulation software and enables quality control and ink compliance seamlessly from ink manufacturer/supplier to customer/plant.

Supports CXF format for both import & export, including spectral definitions.

Provides info in Lab, LCH, XYZ, RGB, and Hex, including all M modes and lighting conditions.

Requires little to no changes at the operator level to harness tracking, analyze data, and turn it into useful information.

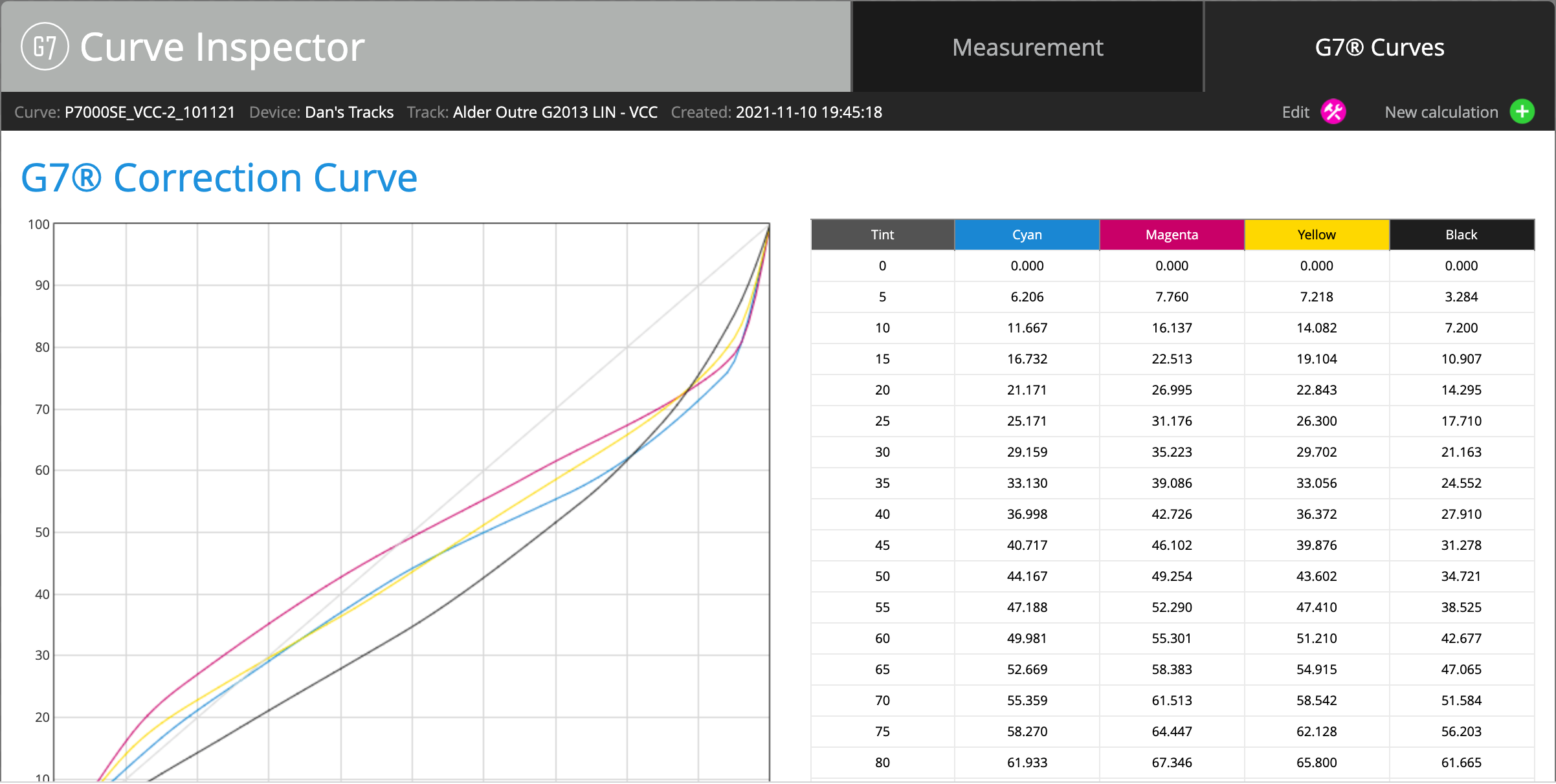

Enables G7 curve generation without dedicated press runs, which can eliminate downtime.

Helps identify operational improvements.

Operators that need color training.

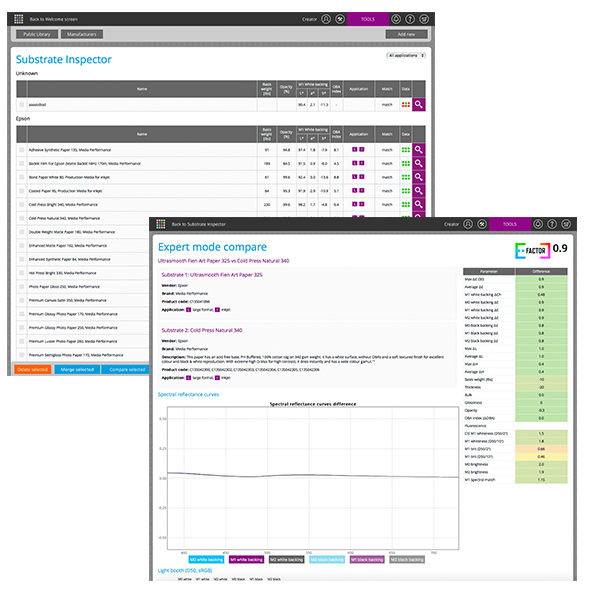

Reveals color problems caused by differing substrates.

Exposes humidity, temperature, and environmental factors impacted.