Understanding & Monitoring Color Drift

by Carrie Watson- Alder Color Solutions

Color drift isn’t caused by one thing. It’s the result of environmental changes, device wear, media variations, ink batches, and operator differences that gradually push your output off target.

Even if you’ve nailed your ICC profiles and calibration routines, color performance can still shift day-to-day — sometimes without visible warning. In a traditional workflow, you only notice once a customer points it out. By then, you’ve already lost time, materials, and confidence.

The Alder Solution: Continuous Color Awareness

The Alder Color Control Platform brings proactive color control to every device in your workflow.

By integrating ChromaChecker and device-level monitoring, Alder gives you real-time insight into how your printers, proofers, and monitors are performing.

Instead of waiting for color issues to appear, the platform automatically verifies every device against target standards — G7, ISO 12647, or your own internal baselines — and alerts you when drift begins.

It’s early warning for your color system, delivered through clear dashboards and automated reports.

How It Works:

Baseline Every Device

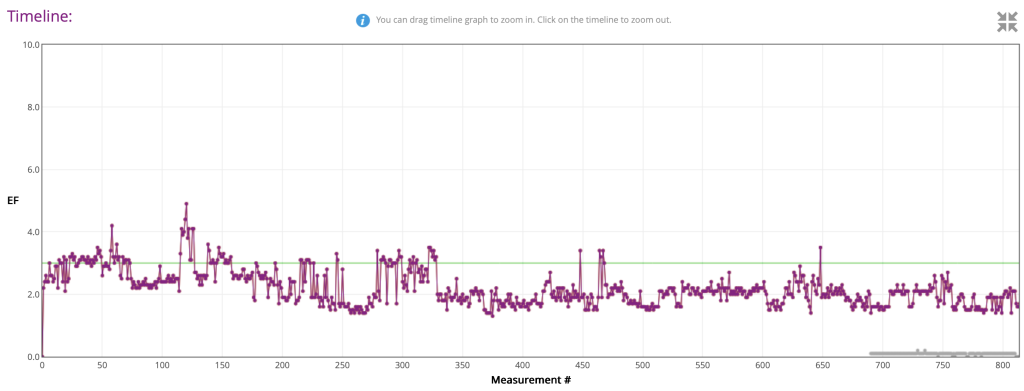

Each printer, display, or proofer gets a verified color baseline. Alder tracks that performance over time, so small deviations become visible before they become problems.

Automate Color Verification Checks

Schedule daily or weekly checks using built-in automation and ChromaChecker targets. The system handles measurement, analysis, and reporting — no guesswork required.

Monitor in Real Time

The Alder dashboard visualizes drift trends across all connected devices, showing you which printers need attention — and which are still perfectly in spec.

Act Before Production Fails

Smart notifications alert you immediately when a printer or substrate starts to deviate, giving your team the chance to correct it before client work is affected.

Why It Matters

- Save time and media by preventing out-of-spec reprints.

- Reduce operator stress with automated checks instead of reactive fixes.

- Prove quality to clients with traceable performance data.

- Protect brand integrity by ensuring consistent color across every output and location.

When your color control is proactive, production becomes smoother, client relationships become stronger, and your brand reputation becomes bulletproof.

Perfect For:

- Print Shops & PSPs managing multiple wide-format printers

- Packaging Teams balancing color across materials and vendors

- Creative Agencies delivering color-accurate brand proofs

- Fine-Art Studios ensuring consistent reproduction across media

- Manufacturing of any color critical print component

Don’t Chase Color — Control It

Reactive color management is a thing of the past. With the Alder Color Control Platform, you can monitor, measure, and maintain color performance before it ever drifts out of spec.

Schedule a Demo

and see how connected color intelligence can transform your workflow.

Email: [email protected]

Phone: 717-475-9007

Contact Dan Gillespie at Alder Color for more info, pricing and consultation. You may need to upgrade your RIP with a new printer option to drive this new printer. We can help!