How to Match Multiple Printers

Calibration of a single printing device is not always the easiest task, so it’s perhaps no surprise that matching multiple printers to each other is a significant challenge. With the rise of digital printing, our commercial printing customers frequently ask: “What is the best way to profile multiple devices of the same model?” The good news is there are tips you can follow to make color-matching across multiple printers a success.

If you are trying to achieve a close visual match between printing devices, there are three key things to consider before putting ink on the sheet:

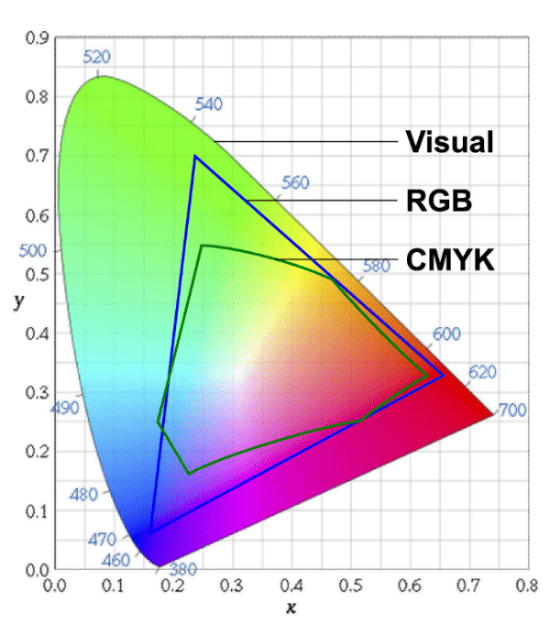

1) Printer gamuts have to be pretty close between devices. This of course has a lot to do with substrate texture and ink texture (rough textured media and/or UV inks both exhibit more light scattering properties due to their roughness vs. solvent on glossy substrates).

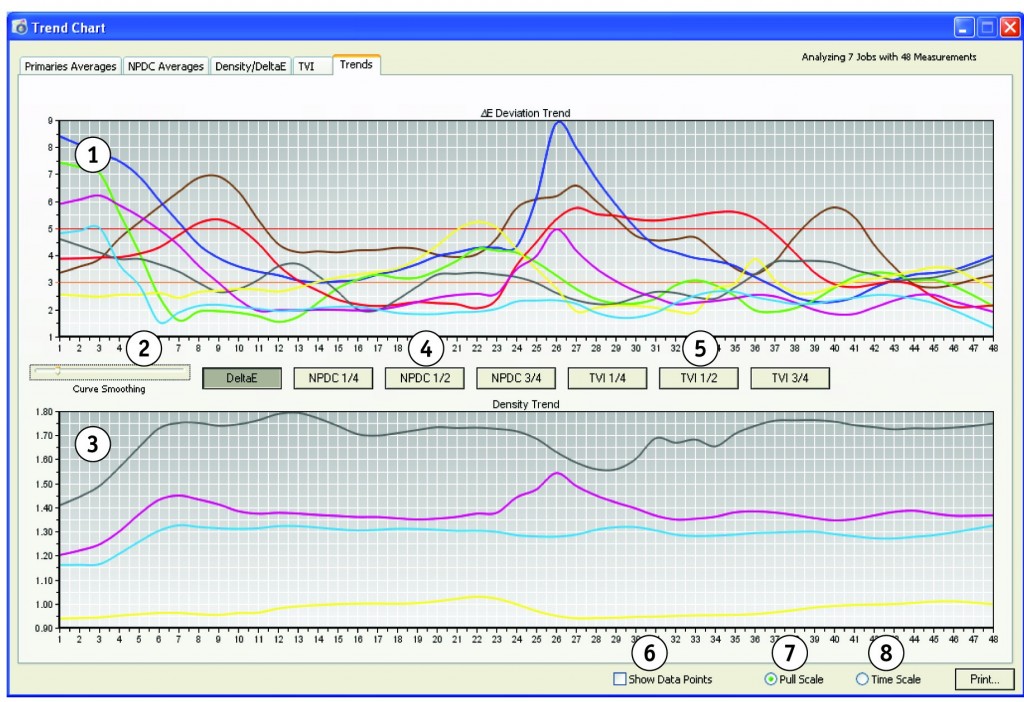

2) It is necessary to evaluate more than just the worst ∆E value. You need to know how all the patches in a control strip compare in ∆E, not just the worst or the average. When choosing a control strip,the more patches, the better, as long as the chart doesn’t become too large for practical daily use. The more patches under 1 ∆E, the more likely the printing is visually close, as you are comparing all patches in the strip to themselves and ranking them on visual closeness.

3) You can’t compare to an industry reference, like GRACoL, when visually comparing devices. You have to compare one device as the reference to the other, because that’s what you’re looking at in the viewing area. You can’t see GRACoL, as there is no perfect GRACoL proof, but you certainly can see the difference between printer A and printer B, so make printer A the reference when comparing those two devices. Hopefully with grouping tests you can compare multiple devices to one device.

Tight calibration of the device and the ability to truly recalibrate back to the same known state the device was in when profiled is key. From my experience, the automated “recalibration” process does not always work well in the field. Some RIPs are better than others, but the bottom line is for true recalibration to work successfully it has to be a two-part process. First, you have to achieve the same solid ink value that was in the original calibration, and second, you have to then create the same curve along the values between 0% and 100%. Most RIPs do the latter, but few actually do the former during the automated recalibration process. This is important, because if you can’t fully recalibrate the printer, the original profile is eventually going to be too far off the mark to be useful.

Also consider: very rarely do two of the exact same devices that are exactly the same age print the same color right out of the box. I’ve proven this many times when evaluating color output data during calibration sessions. There is no way to successfully use a single profile for multiple devices that aren’t even close and achieve a tight visual match. My advice is to target the same source reference space (GRACoL as an example) for each device, then calibrate and profile each device as carefully as possible to achieve as tight a match as the RIP can provide to the source reference space. When finished you can compare how close each device is to one another by printing a test chart and comparing the measured results. Now that being said, RIPs that have iterative optimization have a much better chance of achieving a tight calibration between multiple devices than RIPs that can only rely on ink limits, linearization, and icc profiles alone.

You certainly can and should run comparison tests between all your devices (ideally on a single substrate all devices can print on) to identify which devices are the closest to one another and group them accordingly. The point here is to get to know each and every device (it’s gamut, how consistently it prints, etc.). Maybe you get lucky and find several devices that actually are close enough to calibrate using a single profile. Only after going through the process of calibration and evaluating the results can you truly know the color capability of each device.

I have installed many pairs of Epson aqueous printers and have never found two that calibrate the same or profile the same, however, following the process described above will get them to the closest possible visual match.

SpotOn! Verify is the ideal tool for comparing the calibration results of each printing device. SpotOn! Analyze is the ideal tool for setting ink limits and examining the color differences between each printing device. Try them for yourself!