What is a RIP and should you be printing with one?

A computer and printer speak different languages. The computer language needs to be translated to the printer language so the final print matches what is on the computer screen. If you were to travel to China without knowing Chinese you would need a translator to communicate with the locals. If your artwork does not have a translator for its trip through the printer, the final result could be very unexpected and costly.

Technically speaking, a RIP is software used in a printing workflow. It produces a raster image also known as a bitmap from a page description language such as PostScript, Portable Document Format, XPS or another bitmap of higher or lower resolution than the output device. The bitmap is then sent to a printing device for output.

Quick Tip: What is the difference between raster and vector images?

- Raster images are made of pixels and are a set resolution. Photographs and scans are raster images.

- Vector images are made of points, lines, and mathematical formulas. Certain logos and illustrations are vector images.

- Postscript is used by applications like InDesign, Quark and Illustrator to describe the

page (art) that has been created. Art from these applications can contain both raster

and vector images.

Drivers vs. RIPs

Printer manufacturers usually provide a driver for your printer. These drivers are what you see when you select Print from the File menu within your application (i.e. Word, Acrobat, InDesign, Photoshop, etc.). They are a set of choices and options that control the printer and printing process from within the application you are printing from. Depending on the application you are printing from these drivers help you set paper types and sizes, along with how you are going to convert file colors to the colors the printer can output. As an example, from Photoshop a typical inkjet driver is able to convert RGB raster images to the printer colors with very good accuracy. The feature set of printer drivers is rather limited. Selecting paper, color profiles, and sizing are pretty much the limit to feature that are available.

However, software based RIPs come with a lot more onboard tools for a better workflow. A RIP allows the user to easily gang up multiple images on one sheet to conserve paper, convert colors through ICC profiles, determine how much ink to use for a specific paper, replace spot colors with user-defined color mixes, adjust print quality settings, and turn the paper cutter on or off if the printer is equipped with one.

Continuing with the language analogy, if you are printing with a driver only it is like writing a long, technical email in English and translating it to Chinese using Google Translate. Yes, this would probably change the words, and the person on the other end will probably be able to decipher the dates, times and names of the people involved. However, if you would like the reader to clearly understand critical details, you will need to invest in a professional translator (buying a RIP) to accurately translate your entire message.

Main benefits of printing with a RIP:

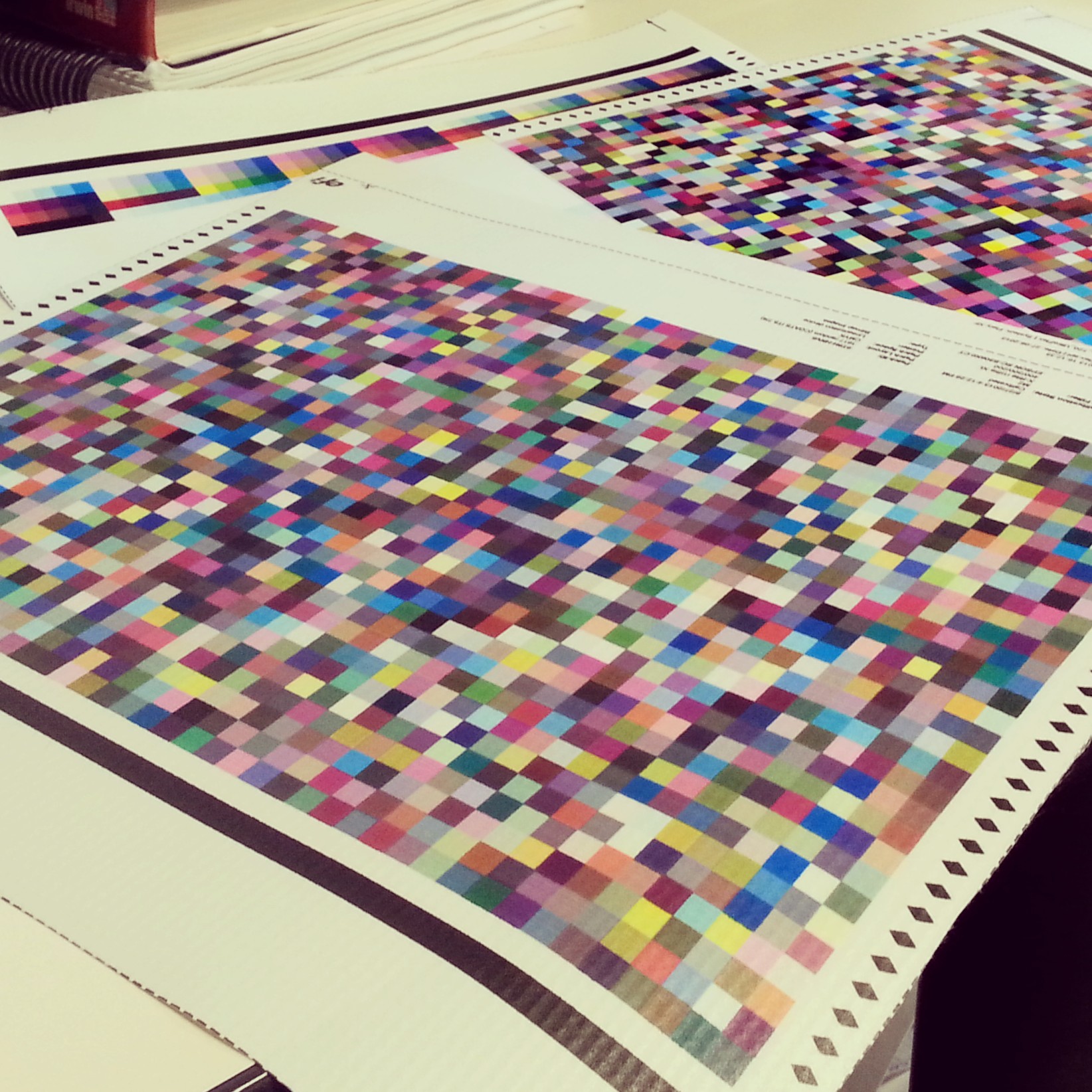

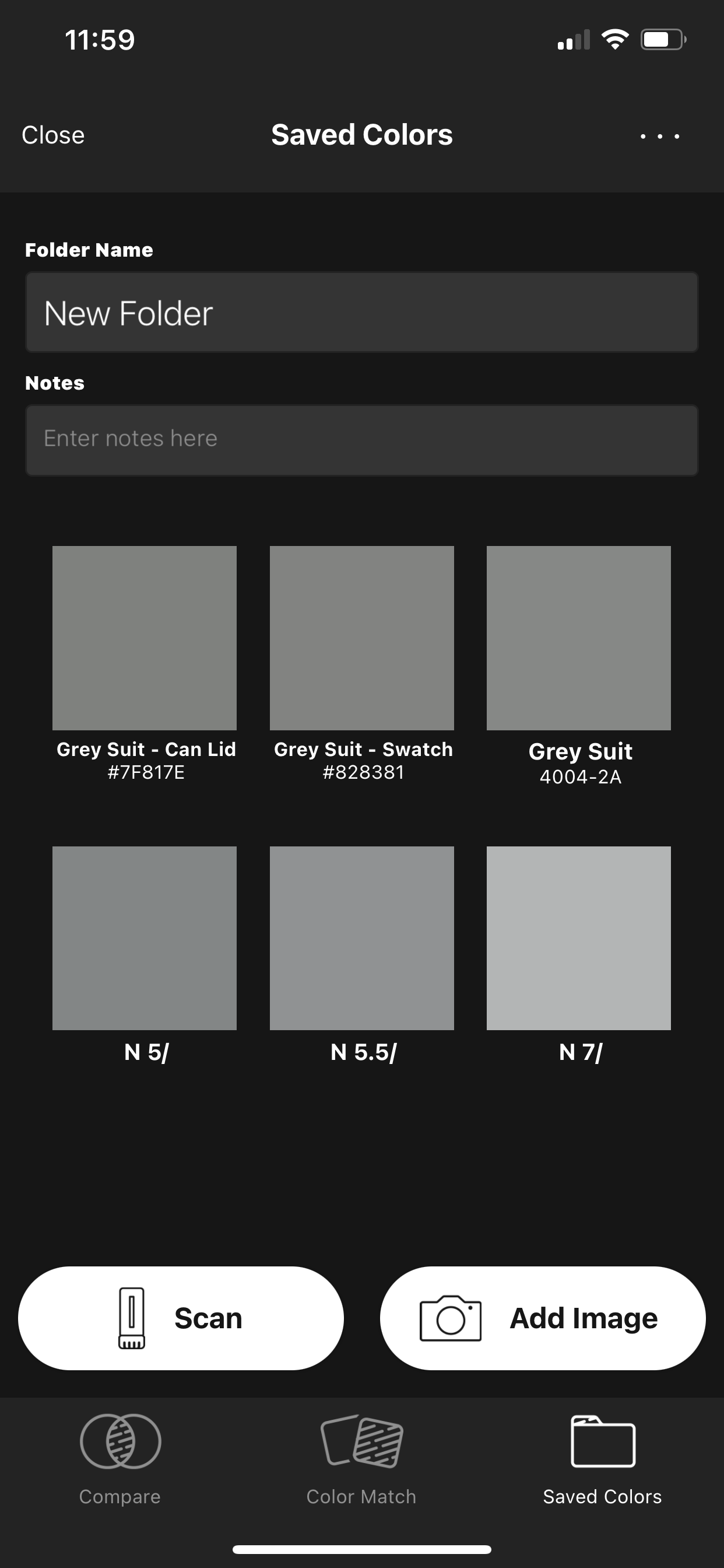

- Ability to calibrate and profile your printer on a specific media for higher color accuracy

- Easy file positioning (scaling, cropping, and rotating)

- Manual or automatic placement of multiple files on a single sheet

- Accurate control over Pantone and other spot colors

- Creates a more efficient printing process with multiple print queues for different media

Quick Tip: What is an ICC Profile and what is a Linearization?

- Linearization sets the printer on a given media to a known and repeatable state. It is an adjustment to the amount of ink printed for each color channel based on how much ink the media can hold. Performing a re-linearization will bring a printer back to the initial linearization state, compensating for any printing variation over time.

- ICC Profiles describe the characteristics of a linearized printer (exactly what colors a printer can print on a given media) and acts as a translator for color. An ICC profile is specific to a printer, substrate, print mode resolution, print direction, etc.

- Read our Blog post on ICC profiles here!

Increasing efficiency and reducing costs in the pre-press environment are vitally important factors in maintaining or improving profitability especially for small to mid-sized print operations. With the proper workflow and tools in place, RIPS make color management as easy as a click of the button!

So do I need a RIP?

“Will printing with only a driver work for me? Or do I need a RIP?” The answer to both is YES! In our experience, when using a RIP we throw far fewer prints away and rip (no pun intended) much less hair from our heads. This is all depending on your printing situation and whether or not it is cost justifiable to do so.

To figure a cost justification, calculate your lost revenue for one year by adding these items up:

- Cost of prints thrown away or rejected

- Cost of reprinting

- Time spent reworking files

- Time spent ganging or compiling files for multi-up printing

The total will give you an indication of how much you could save if you were using a properly calibrated RIP. If this amount is more than the cost of a RIP, computer, installation, calibration and training, then it makes sense to purchase a RIP. If it doesn’t, then keep doing what you are doing.

There are many RIPs on the market with a wide range of features and pricing. If you decide you do need one, Alder is up-to-date on all the latest RIPs and can guide you through the maze of ICC profiles, calibration and color settings to ensure you are getting the most return on your RIP investment.