Color Management 101: Printer Consistency

Let’s be honest, no printing device is truly consistent. Print variance is inevitable. While minor variation over the course of weeks is normal, what you should be concerned with is either a sudden change outside the normal variation or a slow degradation over time. Some variation is mechanical in nature, like a print head getting clogged, and some variation comes from external variables such as temperature and humidity.

It is strongly recommended that you do not alter your files to compensate for printer drift, especially if you print the same files multiple times over any period of time. You will forever be tweaking files chasing your printer variation.

Controlling print consistency can seem a daunting task, however, there are some easy steps you can take to monitor you printer’s behavior. From this information, action can be taken to correct the inconsistency.

If you have a RIP and a Spectrophotometer:

(If you don’t have a RIP or spectro click here for instructions…)

Four easy steps: (requires spectrophotometer)

- Take regular measurements of how your printer is printing

- Graph these measurements in a trend graph to make it easy to see print variation

- Identify normal variation

- Watch for sudden changes and slow degradation

Applying a Fix (with a RIP)

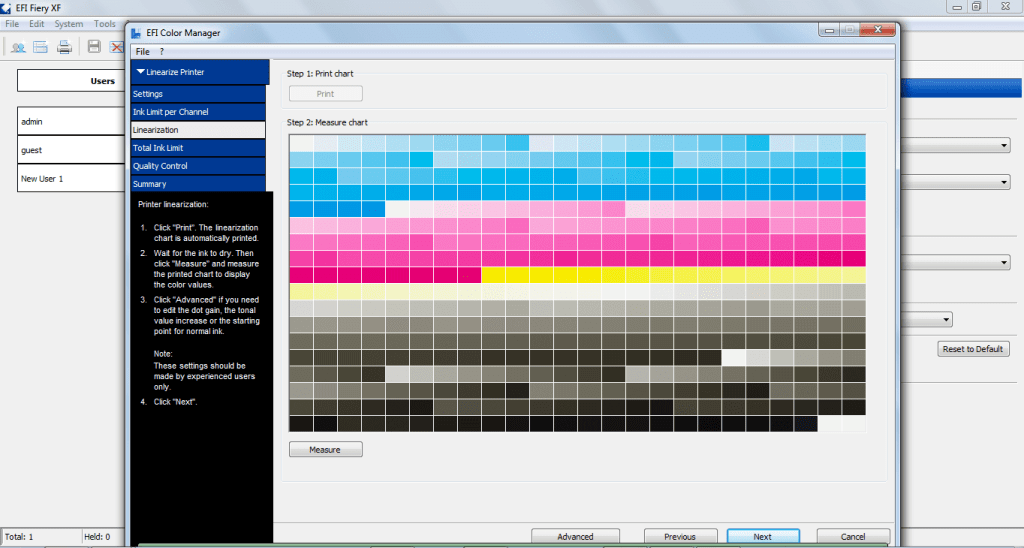

RIPs allow you to recalibrate your printer, giving you the fix that is most effective and makes the most sense to compensate for drift.

*In upcoming blogs we will talk about the different measuring devices, RIPs, and software options and how to use them.

If you don’t have a RIP and a Spectrophotometer:

If you are printing with a simplified workflow and you don’t have a RIP or a measuring device, your options are limited.

The steps:

- Compare a current print to a previously printed sample of the same subject

- If there are significant differences between the two, there are only two options (see Applying a Fix below)

Applying a Fix

Steps you can take if don’t have a RIP:

- Adjust your art files to compensate for the printer drift (not a desirable option as you will be forever adjusting your image library and wasting precious time and resources).

- Have Alder or someone with profiling tools create a custom ICC profile for your current printer and paper configuration. This often will not get you back to your original printer color, but will establish a new baseline for the printer moving forward.

If critical color over time is important to you then consider buying a RIP to implement a truly color managed workflow that can be recalibrated as the printer drifts over time (read this blog to see if it makes sense for you).

Join us for our next blog where we will be talking about color spaces for digital viewing and printing.